PUMP INSTALLATION AND

APPLICATIONS

These pumps are suitable for pumping

clean water and fluids which are not chemically aggressive to

the pump components.

These pumps are an obvious choice

wherever there is a need for high head values hard to reach

with single impeller pumps,all thanks to the following

features:extremely high outputs,suitable for continuous and

heavy-duty use and particularly adaptable to a wide range of

particular applications.

2MC series pumps are extremely

reliable, simple to use, quiet and virtually maintenance-free,

finding many uses in domestic, civil and industrial

applications, the automatic distribution of water from surge

tanks, watering gardens, increasing the mains supply pressure,

feeding boilers, cooling systems and fire-fighting

units.

These pumps should be installed in a covered

area,protected against the weather.

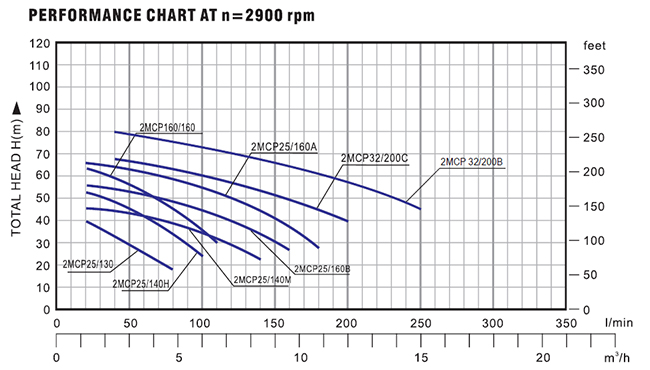

PERFORMANCE

¡ù particularly ample and

stable characteristic curves (high ratio between minimum and

maximum head values);

¡ù outputs having high absolute values

and tendencially flat curves;

¡ù flat absorption curves at

high delivery rates,preventing motor overloading even during

prolonged use;

¡ù good suction capacities both at low and

high delivery rates.

STRUCTURAL CHARACTERISTICS

¡ù cast iron

suction body

¡ù cast iron delivery body

¡ù brass impellers

with centrifugal radial flow type

¡ù stainless steel

shaft(Hi-Cr plated 45# steel up to 0.75kw)

¡ù stainless

steel mechanical seal (graphite to ceramic or graphite to

SiC)

¡ù protection IP 44

¡ù with thermal overload

protector in single phase motor up to 1.5KW

The remaining

single phase motors and all three phase motors require an

adequate external motor protector,with connections according

to current standards.

¡ù NSK bearing or local bearing

WARRANTY:1 YEAR(according to our general sales

conditions)

FLOW RATE Q

PUMP MODEL |

POWER |

Q

m3/h |

0 |

1.2 |

1.8 |

2.4 |

3.0 |

3.6 |

4.2 |

4.8 |

5.4 |

6.0 |

6.6 |

7.5 |

8.4 |

9.6 |

10.8 |

12 |

15 |

Single phase |

Three phase |

KW |

HP |

l/min |

0 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

110 |

125 |

140 |

160 |

180 |

200 |

250 |

| 2MCP 25/130 |

2MC 25/130 |

0.75 |

1 |

H

M

|

44 |

40 |

37 |

34 |

30 |

25 |

22 |

18 |

|

|

|

|

|

|

|

|

|

| 2MCP 25/140H |

2MC 25/140H |

1.1 |

1.5 |

54 |

53 |

51 |

49 |

46 |

42 |

38 |

34 |

29 |

24 |

|

|

|

|

|

|

|

| 2MCP 25/140M |

2MC 25/140M |

1.1 |

1.5 |

47 |

46 |

45.5 |

44 |

43 |

42 |

41 |

38 |

36 |

34 |

31 |

28 |

22 |

|

|

|

|

| 2MCP 160/160 |

2MC 160/160 |

1.5 |

2 |

66 |

64 |

62 |

60 |

57 |

53 |

49 |

44 |

39.5 |

35 |

30 |

|

|

|

|

|

|

| 2MCP 25/160B |

2MC 25/160B |

1.5 |

2 |

58 |

56 |

55 |

54 |

53 |

52 |

50 |

48 |

46 |

44 |

41 |

39 |

33 |

26 |

|

|

|

| 2MCP 25/160A |

2MC 25/160A |

2.2 |

3 |

68 |

66.5 |

65.5 |

65 |

63 |

62 |

60 |

58 |

56 |

54 |

51 |

48 |

42 |

35 |

28 |

|

|

| 2MCP 32/200C |

2MC 32/200C |

3 |

4 |

70 |

- |

- |

66 |

65.5 |

65 |

63 |

63 |

61 |

60 |

59 |

57 |

53 |

48 |

45 |

40 |

|

------- |

2MC 32/200B |

4 |

5 |

82 |

- |

- |

79.5 |

78.5 |

77.5 |

76.5 |

75.5 |

74.5 |

73.5 |

72 |

71 |

67.5 |

64.5 |

61 |

57 |

45.5 |

H=TOTAL HEAD IN METERS. Q=FLOW

RATE

|